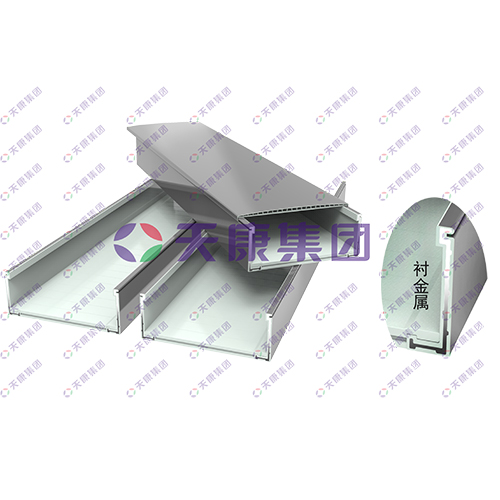

Metal lined polymer bridge

- Tel:0550-7989666、0550-7989999

- Fax:0550-7989666

- Mail:tkjd@tiankang.com

Description

Product introduction

The macromolecule alloy cable tray, which was researched and developed by Anhui Tiankang (Group) Shares Co., Ltd. The double hollow structure design and ASA double layer co extrusion process are adopted. The double hollow structure is based on the principle of mechanical structure, so that the weight of the product is lighten and the bearing capacity is strengthened. At the same time, it can play a good heat dissipation effect. The application of ASA double layer co extrusion technology greatly improves the product's anti-aging and anti-UV properties, prolongs the service life of the product, and makes the matte surface with special technology more durable. The product has been tested and qualified by the national electric power distribution equipment quality supervision and inspection center. It has many advantages, such as high strength, corrosion resistance, anti-aging, light weight, flame retardant, long service life and green environmental protection. It is the best product for upgrading and upgrading conventional cable tray, and it can completely realize "plastic instead of steel".

Scope of application

Macromolecule alloy cable tray is suitable for laying of power cable、 control cable、 computer cable、 lighting wiring and other indoor and outdoor overhead, cable trench and cable tunnel.

Three innovations:

1. Formulation process innovation Adopts polymer organic materials, with high impact strength, good dimensional stability and excellent corrosion resistance.

2. Production process innovation Adopts twin-screw extrusion process, ASA double-layer co extrusion process, which has strong plasticizing ability and good mixing effect.

3. Product structure innovation Adopts double-layer hollow structure design, self- weight reduction, easy heat dissipation, bearing capacity enhancement.

Nine advantages:

1. High strength 2. Corrosion resistance 3. Light weight 4. Environmental protection 5. Non-conductive 6. Flame retardant 7. Beautiful appearance 8. Long life 9. Easy to install

Model identification method

1)General terms

TK | - | P | □□Q | - | □ | - | □×□ |

Company abbreviation | - | Material code | Structure | - | Other attachment code | - | Cable tray B×H |

2) Material code、Structure

Double side | Sandwich type | Combined type | Channel type | Ladder type | Pallet type | Long span type |

D | FX | ZH | C | T | P | D |

Performance table of Cable tray

No. | Name | Performance |

1. | Material properties | Macromolecule plastic cable tray |

2. | Bearing capacity | High strength with two properties of steel toughness |

3. | Product appearance | artistic |

4. | Anti-leakage safety grounding | No grounding requirement |

5. | Anti-aging | Suitable for any environmental conditions, long service life |

6. | Temperature resistance | No harmful substances will be produced under high temperature, with good heat insulation |

7. | Withstand voltage performance | good |

8. | Oxygen index | Flame retardant, oxygen index up to 44, class I flame retardant (the product will automatically extinguish within 1 second from the fire) |

9. | Corrosion resistance | No chemical reaction in corrosive environment |

10. | Shielding performance | good |

11. | Water resistance | good |

12. | Site change | easy |

13. | weight | light |

14. | Installation aging | Fast installation without bolt connection |

15. | Defective rate during installation | Standardized breakdown and transportation, on-site installation, low defective rate |

16. | Is there any negative effect | The inner wall is smooth, and the cable sheath will not be damaged during laying |